PowerFlex 755 VFD Fault Codes⁚ A Comprehensive Guide

This guide provides a thorough understanding of Allen Bradley PowerFlex 755 drive fault codes, offering valuable insights into troubleshooting and maintenance. You can find detailed information on fault codes, their causes, and effective troubleshooting techniques. This document aims to empower you to resolve issues efficiently and maintain optimal performance of your PowerFlex 755 VFD.

Introduction

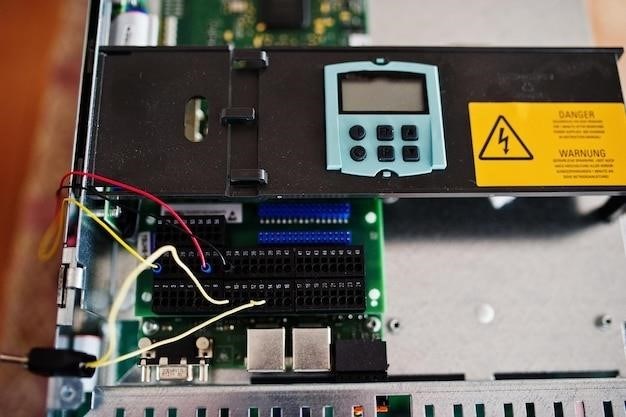

The PowerFlex 755 Variable Frequency Drive (VFD) is a robust and versatile motor control solution widely used in industrial applications. However, like any complex electronic device, it can experience malfunctions, leading to operational disruptions; Understanding and interpreting PowerFlex 755 fault codes is crucial for effectively diagnosing and resolving these issues. This comprehensive guide aims to demystify the world of PowerFlex 755 fault codes, providing a clear understanding of their meaning, potential causes, and recommended troubleshooting steps.

By delving into the intricacies of PowerFlex 755 fault codes, we empower users to confidently identify and address drive problems. This knowledge enables quicker resolution of issues, minimizing downtime and ensuring smooth operation of critical machinery. Whether you are a seasoned technician or a novice user, this guide will serve as an invaluable resource for understanding and effectively troubleshooting PowerFlex 755 VFD fault codes.

Understanding PowerFlex 755 Fault Codes

PowerFlex 755 fault codes are alphanumeric codes displayed on the drive’s LCD screen or through communication interfaces. They represent specific conditions that indicate a potential problem with the drive or its connected system. These codes provide valuable insights into the nature of the issue, allowing technicians to efficiently pinpoint the root cause and implement appropriate solutions.

The fault code system is designed to be comprehensive and informative, encompassing a wide range of potential issues. Each code corresponds to a specific fault condition, providing a clear indication of the problem area. For instance, a code related to input phase loss suggests a problem with the power supply to the drive, while a code associated with overcurrent signals an overload situation.

By understanding the meaning behind each fault code, technicians can effectively diagnose and resolve issues, ensuring optimal performance and minimizing downtime. The PowerFlex 755 fault code system is a crucial tool for maintaining the reliability and efficiency of these drives, making it essential for users to familiarize themselves with this valuable diagnostic resource.

Common Fault Codes and Their Causes

Understanding common PowerFlex 755 fault codes and their underlying causes is crucial for effective troubleshooting. Here are some of the frequently encountered codes and their potential root causes⁚

- Fault Code 17⁚ Input Phase Loss⁚ This code indicates a loss of power supply to one or more phases of the drive’s input. The cause could be a faulty power supply, a blown fuse, a loose connection, or a problem with the wiring.

- Fault Code 24⁚ Overcurrent⁚ This code signifies that the drive’s output current exceeds the set limit. The cause could be an overloaded motor, a mechanical problem within the motor or driven equipment, or a fault within the drive itself.

- Fault Code F13⁚ Ground Fault⁚ This code indicates a ground fault, which means that there is an unintended path for current to flow to ground. The cause could be a damaged insulation, a faulty component, or a wiring issue.

These are just a few examples of common PowerFlex 755 fault codes. It’s important to consult the PowerFlex 755 user manual or other documentation for a complete list of codes and their corresponding causes. By understanding these codes and their potential causes, technicians can quickly diagnose and resolve issues, ensuring optimal operation and minimizing downtime.

Fault Code 17⁚ Input Phase Loss

Fault code 17, “Input Phase Loss,” signals a disruption in the power supply to one or more phases of the drive’s input. This signifies a potential issue with the power source, wiring, or drive components. Understanding the possible causes of this fault is key to efficient troubleshooting. Here’s a breakdown of common reasons behind this code⁚

- Faulty Power Supply⁚ A malfunctioning power supply unit can lead to a loss of input phases, resulting in fault code 17. Inspect the power supply for any signs of damage or overheating;

- Blown Fuse⁚ A blown fuse in the input circuit can interrupt the power supply to the drive. Check the fuse for continuity using a multimeter.

- Loose Connection⁚ Loose connections in the input wiring can cause intermittent or complete loss of input phases. Inspect all connections for tightness and ensure proper contact.

- Wiring Issue⁚ Problems with the input wiring, such as a short circuit or broken wire, can also cause fault code 17. Carefully inspect the wiring for any damage or signs of wear.

By systematically addressing these potential causes, you can effectively troubleshoot and resolve the “Input Phase Loss” issue, restoring the PowerFlex 755 drive to operational status.

Fault Code 24⁚ Overcurrent

Fault code 24, “Overcurrent,” indicates that the drive has detected an excessive current draw, exceeding its rated capacity. This condition can arise from various factors, ranging from motor issues to load imbalances. Understanding the possible causes behind this fault is crucial for successful troubleshooting. Here’s a breakdown of common reasons for overcurrent⁚

- Motor Overload⁚ The most common reason for overcurrent is a motor overload. The motor may be attempting to drive a load that exceeds its rated capacity. Check the load characteristics and ensure they align with the motor’s specifications.

- Mechanical Issues⁚ Mechanical problems, such as bearing friction, misalignment, or a seized rotor, can increase the motor’s current draw, leading to overcurrent. Inspect the motor for any signs of mechanical wear or damage.

- Load Imbalance⁚ An uneven load distribution across the motor phases can cause an overcurrent condition. Ensure the load is balanced and distributed evenly across the motor phases.

- Drive Fault⁚ In some cases, the overcurrent fault may be caused by a malfunctioning drive component, such as a faulty IGBT module. Check the drive’s status indicators and access the fault logs for further information.

By systematically addressing these potential causes, you can effectively troubleshoot and resolve the “Overcurrent” issue, ensuring the safe and reliable operation of your PowerFlex 755 drive.

Fault Code F13⁚ Ground Fault

Fault code F13, “Ground Fault,” signifies a potentially dangerous situation where electrical current is flowing to ground. This fault indicates that a portion of the drive’s electrical system is in direct contact with ground, posing a risk of electrical shock or equipment damage. To effectively troubleshoot this fault, it’s essential to understand the potential causes and take appropriate steps to address them. Here’s a breakdown of common reasons for a ground fault⁚

- Faulty Wiring⁚ A common cause of ground faults is faulty wiring. Inspect the drive’s wiring for signs of damage, corrosion, or loose connections. Ensure all wiring is properly grounded and insulated.

- Motor Winding Fault⁚ A ground fault can also occur due to a fault in the motor windings. Inspect the motor windings for any signs of damage or insulation breakdown. A damaged winding can allow current to flow to ground.

- Component Failure⁚ A failed drive component, such as a capacitor or IGBT module, can lead to a ground fault. Check the drive’s status indicators and fault logs for any clues about a faulty component.

- Environmental Factors⁚ Exposure to moisture, dust, or other environmental factors can degrade insulation and create a path for current to flow to ground. Ensure that the drive is installed in a clean, dry environment.

Resolving a ground fault requires a thorough investigation to pinpoint the root cause. Once identified, appropriate repairs or replacements can be made to restore the drive’s safety and functionality.

Troubleshooting PowerFlex 755 Faults

Troubleshooting PowerFlex 755 faults is a systematic process that involves identifying the root cause of the fault, taking corrective action, and verifying the resolution. The PowerFlex 755 drive offers several tools and techniques to assist in troubleshooting, including⁚

- Status Indicators⁚ The drive’s status indicators provide visual cues about the drive’s operating state and any faults that may have occurred. These indicators can be crucial in narrowing down the potential cause of the fault.

- Fault Logs⁚ The PowerFlex 755 drive maintains a fault log that records the history of faults that have occurred. Examining the fault log can provide valuable information about the sequence of events leading up to the fault.

- Parameter Settings⁚ The drive’s parameter settings can affect its operation and potentially contribute to faults. Review the parameter settings to ensure they are correctly configured for the specific application.

- Communication Interface⁚ The PowerFlex 755 drive can be accessed through a communication interface, such as RS-485 or Ethernet. This interface allows for remote monitoring, fault diagnostics, and parameter adjustments.

- Troubleshooting Tools⁚ Rockwell Automation provides a variety of troubleshooting tools, including the PowerFlex 755 User Manual, knowledgebase articles, and online forums. These resources can provide detailed information about fault codes, troubleshooting techniques, and common issues.

By systematically examining the drive’s status indicators, fault logs, parameter settings, and communication interface, you can effectively diagnose and resolve PowerFlex 755 faults.

Resetting the Drive

Resetting a PowerFlex 755 drive is a common troubleshooting step that can clear temporary faults and restore normal operation. There are several methods for resetting the drive, depending on the specific fault and the desired outcome⁚

- Power Cycle⁚ Turning off the drive and then back on can often clear temporary faults, such as communication errors or software glitches. This simple step can sometimes be sufficient to resolve the issue.

- Reset Button⁚ Some PowerFlex 755 drives have a dedicated reset button on the front panel. Pressing this button will reset the drive’s internal logic and clear any stored fault conditions. This is a quick and easy way to reset the drive if a fault has occurred.

- HMI Reset⁚ If the drive is connected to an HMI (Human Machine Interface), the HMI may have a dedicated reset function for the drive. This allows you to reset the drive from the HMI without physically accessing the drive itself.

- Parameter Reset⁚ The PowerFlex 755 drive allows for resetting specific parameters to their factory default values. This can be useful if a parameter has been inadvertently changed, or if you want to start fresh with the drive’s settings.

It’s important to choose the appropriate reset method based on the specific fault and the desired outcome. Always consult the PowerFlex 755 User Manual for detailed instructions on how to reset the drive.

Using the Drive’s Status Indicators

PowerFlex 755 drives are equipped with a set of status indicators that provide valuable information about the drive’s operating state and any potential problems. These indicators can be a crucial tool for quickly identifying and troubleshooting faults.

The status indicators typically include LEDs (Light Emitting Diodes) that illuminate in different colors or patterns to indicate various conditions. These indicators can display the following information⁚

- Power Status⁚ Indicates whether the drive is receiving power and is ready to operate.

- Fault Status⁚ Illuminates to signal that a fault has occurred. The color or pattern of the light may indicate the specific type of fault.

- Run Status⁚ Indicates whether the drive is currently running or in a standby mode.

- Communication Status⁚ Shows the status of communication between the drive and other devices, such as the HMI or PLC.

By carefully observing the status indicators, you can quickly gain insights into the drive’s operation and identify any potential issues. Refer to the PowerFlex 755 User Manual for a detailed explanation of the specific status indicators and their meanings.

Accessing Fault Logs

PowerFlex 755 drives keep a record of past faults, providing valuable insights into troubleshooting and preventative maintenance. Accessing these fault logs can help identify recurring issues, understand the sequence of events leading to a fault, and determine the root cause of a problem.

To access the fault logs, you will typically use a programming device or software application connected to the drive. The specific method for accessing the logs may vary depending on the configuration and software tools you have available.

The fault logs typically contain information about the following⁚

- Fault Code⁚ The specific code indicating the type of fault that occurred.

- Timestamp⁚ The date and time when the fault occurred.

- Fault Description⁚ A brief description of the fault condition.

- Fault Severity⁚ The level of severity of the fault, such as minor, major, or critical.

- Fault History⁚ A record of previous faults and the actions taken to resolve them.

By analyzing the fault logs, you can gain valuable information to understand the history of the drive, diagnose recurring issues, and make informed decisions about maintenance and repairs.

PowerFlex 755 Documentation and Resources

Accessing comprehensive documentation and resources is essential for effective troubleshooting and maintenance of PowerFlex 755 drives. These resources can provide detailed information about fault codes, their causes, and recommended solutions. They can also offer valuable insights into the drive’s configuration, operation, and troubleshooting techniques.

One of the most important resources is the PowerFlex 755 User Manual. This document provides a comprehensive overview of the drive’s features, operation, and troubleshooting procedures. It includes detailed descriptions of fault codes, their potential causes, and recommended actions to resolve them. The manual also covers topics such as installation, configuration, and communication protocols.

Another valuable resource is the Rockwell Automation Knowledgebase. This online database contains a vast collection of technical articles, troubleshooting guides, and application notes related to PowerFlex drives. You can search the knowledgebase for specific fault codes, issues, or topics to find relevant information and solutions.

By utilizing these documentation and resources, you can gain a deeper understanding of the PowerFlex 755 drive, enhance your troubleshooting skills, and ensure optimal performance of your equipment.

PowerFlex 755 User Manual

The PowerFlex 755 User Manual is an indispensable resource for understanding and troubleshooting PowerFlex 755 drives. This comprehensive document provides a detailed overview of the drive’s features, operation, and troubleshooting procedures. It includes valuable information on fault codes, their potential causes, and recommended actions to resolve them. The manual also covers topics such as installation, configuration, and communication protocols.

The PowerFlex 755 User Manual is available in PDF format, making it easily accessible and convenient for reference. It can be downloaded from the Rockwell Automation website or obtained from your local authorized distributor. The manual is organized in a clear and logical manner, with sections dedicated to specific topics, including fault codes, troubleshooting, and maintenance procedures. It also includes helpful diagrams, illustrations, and tables to enhance understanding and facilitate troubleshooting.

The PowerFlex 755 User Manual is a valuable tool for anyone working with PowerFlex 755 drives. It provides the essential information needed to understand the drive’s functionality, troubleshoot issues, and ensure optimal performance.